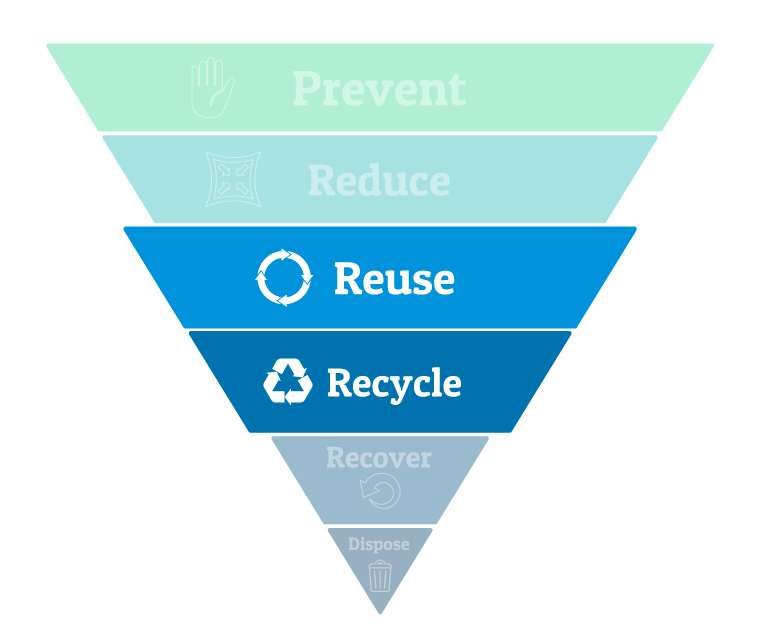

Recycling is generally perceived as a great way to help reduce waste production, and that indeed extends to the construction industry.

Whilst many consider recycling to be the ultimate solution to the Earth’s environmental problems, the practical application of recycling often means it is more complicated than people initially realise.

We at Clear It Waste, are here to make this process easier for you and remove the hassle of trying to recycle construction waste yourself.

Some of the most common construction waste materials include:

- Steel

- Paper

- Concrete

- Glass

- Wood

- Plastic

- Asphalt

- Copper

- Plaster

- Aluminium

- Bricks

- Insulation materials

Recycling construction waste is important and no one knows this better than we do, here at Clear It Waste. Our team of experts are fully trained and experienced in dealing with a range of different building materials – particularly construction waste. No job is too small or too big for us – with our dedicated fleet of waste clearance vehicles and reliable staff, we can attend within hours of receiving your call.

How to recycle different types of construction waste:

Steel

Due to its high tensile strength and low cost, steel is one of the most popular materials used within the construction industry.

Many buildings – including houses, car parks, schools, hospitals and skyscrapers – rely on steel as an integral part of their infrastructural support. It is also used on roofs and as cladding for external walls.

Pros of recycling steel

- It is one of the easiest materials to recycle

- 100% recyclable

- It can be recycled over and over again without losing its quality or integrity.

- The environmental impact of recycling steel is also lower than that of generating new steel from raw materials – improving your environmental business credentials

However, steel has to go through a number of processes before it can be recycled including shredding, melting and purification. Due to its excess weight, there are also additional transportation costs.

Concrete

There is twice as much concrete used in construction than all of the other materials combined.

The mechanical strength and durability make concrete a long term solution to many construction projects, such as buildings, bridges, roads and dams.

Pros of recycling concrete

- Cheaper and more ecologically friendly than trucking it to landfill

- Can be used to create high-grade construction materials for road gravel, retaining walls or raw materials for new concrete

- Can be reused multiple times without losing integrity

However this is an intensive process as trash materials need to be removed first and some parts need to be done by hand, making it labour intensive.

There are also financial implications of trying to recycle it yourself such as purchasing crushing machines and transporting waste to a site.

Wood

Recycling is not necessarily the first thing that comes to mind when considering what to do with wood waste.

Construction wood waste can range from sheets of medium-density fibreboard (MDF) to tree branches to wooden pallets and crates.

Pros of recycling wood

- Most types of timber can be recycled

- Wood can be chopped down and turned into other building materials – such as composite sheet material, landscaping materials and pathways

- Reduces deforestation and the removal of raw materials from the environment – improving your environmental credentials

Practically, should you try and recycle this yourself, you are likely to be faced with a number of obstacles surrounding contaminants, such as glue and nails, which have to be completely removed first.

Asphalt

95% of the UK’s asphalt is used in the construction of roads and pavements. But it is also used for roofing as a waterproof sealant, known as bitumen, as well as airport runways and tennis courts.

Pros of recycling asphalt

- It is 100% recyclable – making the process very efficient

- Can often be stronger and more resistant than new asphalt

- Can often be cheaper to recycle than create new aggregate mixes every time – saving you money

- Less waste sent to landfill – saving you money in disposal costs

- More permeable so helps with drainage of water during heavy rain events

However, this process requires intensive pulverisation and sortation according to size, before being transported to a central plant. This is time-consuming and expensive.

Plasterboard

Plaster is a building material used for the protective or decorative coating of walls and ceilings on the interior of buildings. The most common forms of plaster contain gypsum, lime or cement, but all work in similar ways to form or line the inner walls of buildings.

These materials are defined as hazardous and can no longer be sent to landfill with biodegradable waste, therefore this should increase the amount of plasterboard available for recycling.

Pros of recycling plaster

- Offcuts can be recycled very easily as they are less likely to be contaminated

- Recycled gypsum can be recycled into other materials – such as cement and Plaster of Paris as well as a soil neutraliser in agriculture.

- No need to use waste transfer notes as you are recycling the material instead of transporting and disposing of it

However, practically and logistically, this is one of the more difficult construction waste materials to recycle, should you wish to do it yourself.

As businesses tend to produce a large volume of plasterboard waste, you have a duty of care to ensure this is done in a responsible way or face fines from the Environment Agency.

There are a number of strict protocols for recycling plasterboard set out by the government for you to follow on this – so why not let Clear It Waste take care of this political headache for you and avoid the risk of facing financial or legal action for not following the protocols.

Bricks

Bricks are used to build walls, pavements and other elements of masonry construction as well as more complex features such as fireplaces, arches and chimney stacks.

They remain popular to this day due to their relatively lightweight properties, making them easy to handle and increase strength when compressed and joined together with mortar (cement).

They require very little maintenance and are extremely durable, which means they can be made up into complex structures that look visually very appealing.

Pros of recycling bricks

- Can be broken down and used for a variety of purposes including aggregate, landscaping, producing new bricks and plant substrate

- Made using high-quality firing techniques

- Pre-used bricks have been pre-weathered which means they are less likely to shrink or expand with the changing weather conditions

- Up to 20% cheaper than buying most new bricks – saving you money

However, before rushing into doing this yourself, you need to be aware of the complications surrounding the recycling process.

Bricks can become contaminated very easily from other forms of construction waste. Therefore the cleaning process is essential. However, this is very time consuming and requires intensive cleaning processes, which is also energy-dependent. You also need to have access to appropriate facilities or be able to transport them; both of which are expensive.

Paper

Paper is a material we use in our everyday lives, but through its production, it contributes 5% towards global industrial carbon emissions.

Within the construction industry, paper is used for a variety of uses including invoices, letters, drawings and packaging material. Kraft paper – a type of reinforced paper – is also a valuable material used to keep things in pristine condition such as protecting work surfaces or covering windows to deter criminals.

Pros of recycling paper

- It is one of the easiest materials to recycle

- Can be recycled several times before the quality diminishes

- Reduces air and water pollution

- Uses fewer raw materials – such as wood pulp – leading to less deforestation

- Cellulose fibres from waste paper can be turned into effective insulation material or wood pulp could be used to design the roads of the future

However, paper has to go through a number of processes before it can be recycled including cleaning and drying.

Glass

Glass is commonly used in the construction industry for windows, doors, ceilings and floors.

It has a distinct ability to retain heat, making it popular for conservatories and greenhouses.

Pros of recycling glass

- 100% recyclable

- Can be recycled indefinitely (in most cases)

- Can be used to make many useful items such as containers, fibreglass and sand

- Reduces CO2 emissions and demand for extraction of raw materials such as limestone – reducing your carbon footprint

- Takes 40% more energy to produce glass from raw materials – so saves you energy and money

However, should you try and recycle this yourself, you are likely to come across some barriers.

Prior to being recycled, glass has to be cleaned and purified which is an intensive process. It needs to be detached from any other waste products (e.g. wood) and then separated according to colour. There are also additional costs with recovering, collecting and transporting the glass to an appropriate recycling facility.

Plastic

It has been well documented in the news over recent years about the amount of plastic waste that has been generated and the resulting environmental impacts.

Commonly in the construction industry, waste is produced from packing (about 25%) and the offcuts and unused materials from projects including pipework, insulation and interior fittings.

Pros of recycling plastic

- Many types of plastic can be recycled; in fact, all polymers are technologically 100% recyclable

- Can be turned into other materials that can be used in the construction industry – such as lumber and carpet

- Materials are strong, durable, lightweight and easy to mould – perfect for the construction industry

However, this is a difficult process to try and organise yourself which can turn out to be time-consuming and not cost-effective.

Initially, plastics need to be sorted into their appropriate types and as different plastics are made from different chemicals, this can further complicate the process. There are also additional costs associated with the removal, transportation and sortation.

Copper

Copper is most commonly used in the construction industry for pipes, cladding and communication cables. Its resistance to corrosion and low thermal expansion makes it resistant to deterioration from ground movement, and so highly suitable for underground construction projects.

Pros of recycling copper

- It is 100% recyclable

- Decreases demand for copper mining and preservation of minerals for longer – making it more sustainable

- Reduction in waste products from the refining and smelting process of creating new copper – more environmentally friendly

However, there are complications that you may come across when recycling your copper waste.

It will need to be purified and separated from other metals in order to be recycled. This is a time and labour intensive process. You also need to make sure you have access to the appropriate facilities, which are not that common.

Aluminium

Aluminium is widely used in the construction industry due to its low density and its resistance to corrosion. It is often used on the external facades of buildings, roofs, windows and doors as well as internally for shelving and staircases.

Its low maintenance costs and anodized or lacquered effects make it a popular choice within the building trade and its reflective properties help to reduce energy consumption.

Pros of recycling aluminium

- Reduces the demand for mining raw materials – making it a more sustainable option

- It saves energy consumption (it takes 95% less energy to recycle than produce new aluminium) – saving you money

- Reduces pressure on landfill as aluminium takes a long time to decompose – improving your environmental credentials

- Significant reduction in greenhouse gas emissions by up to 97% compared to producing new aluminium – reducing your carbon footprint

However, should you decide to do this process yourself, you are likely to find that it is a very expensive and energy-intensive process – aluminium has an extremely high melting point of 660℃.

You will need to sort the aluminium from other metals first, which is labour intensive and time-consuming. Finally, there are the transportation and shipping costs, adding an additional financial burden.

Insulation materials

Insulation materials can cover a range of products from fibrous materials such as fibreglass, wool, cellulose and natural fibres to rigid foam boards and foils. Click here for a full breakdown of different insulation materials.

They are often used to resist the conductive and convective heat flows within building cavities, either through trapping air to resist heat flow or reflecting heat away from living spaces.

Pros of recycling insulation materials

- Can be turned into new products – such as compressed stone wool for ceiling tiles, concrete blocks and fibreglass boards

- Reduces greenhouse gas emissions (for example recycling 1000 tons of fibreglass in cement manufacture saves up to 450 tons of coal) – improving your company’s carbon footprint

- Recycling processes produce no ash, dust or residues – improving air quality

- Can be ground down into a powder and added to a resin to make furniture

However, recycling insulation waste is far from an easy process. It can become easily contaminated in the demolition process so needs to be cleaned and purified. Screws and nails need to be completely removed in order to reprocess the waste into new materials.

There is also a lack of specialised facilities – you will need to pay for transportation costs anyway but the chances are these will be higher in order to access the necessary recycling plants.

Why Choose Clear It Waste

Construction waste can be notoriously difficult to get rid of and there are often a number of practical hurdles to overcome in order to achieve this. Here at Clear It Waste, we have the expertise, and the means, to remove all of these barriers for you.

Some materials can become easily contaminated making the recycling process more difficult and time-consuming. Don’t spend time doing these processes yourself – we are on hand to organise all of this for you from collection to sortation to transportation.

Sometimes, it can be hard to know who can recycle your waste – which is where we come in! Our experienced and dedicated staff have the resources and skills to take care of these processes for you, saving you time, effort and money that can be better spent on other areas of your business.

We offer waste collection and recycling all across London to ensure that you can recycle as much of your waste as possible, in an environmentally sensitive way and without all of the associated hassle of organising it. You can be safe in the knowledge that your waste will boost the environmental credentials of your business without costing you valuable time and money trying to recycle your own waste yourself.

1.

Get in touch for your free, no-obligation quote.

2.

Book your collection online or with our friendly team.

3.

We collect your waste and leave your area clean and tidy.